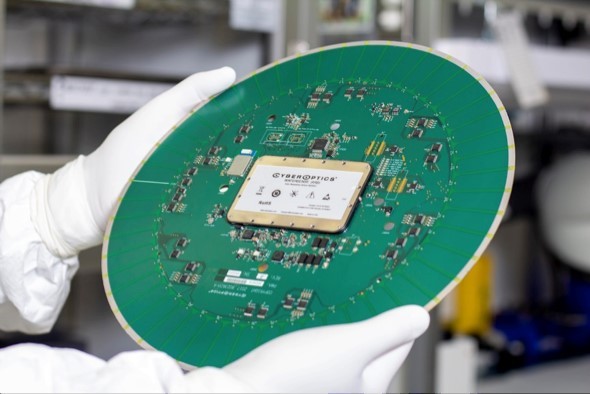

Nordson Test & Inspection - WaferSense® Auto Resistance Sensor™ (ARS)

Real Time Resistance Measurement:

- Quickly monitors and identifies resistance measurements with 50 separate measurement pads

around the perimeter, utilizing Kelvin Sensing (4-wire resistance) method for accurate

measurement of low value resistance

Shorten equipment maintenance cycles with wafer-like 4-wire resistance sensor:

- Collect and monitor real time measurement of contact resistance plating cells to detect residue

affecting plating pins. Thinner wafer-like form factor allows ARS to be handled like any other

wafer in the tool. Save time and costs associated with metrology wafer measurements.

Predict when a tool needs maintenance with quantitative analysis of measured mean resistance over time:

- Optimize preventative maintenance plans with accurate, repeatable data trends. Record data to

enable comparison between past and present, as well as one tool to another with new

CyberSpectrum™ software. Establish and save a baseline from a known clean and new contact

ring. Compare mean resistances to baseline values and receive early warnings for non-uniform

deposition associated with changes to plating pins:

Improve cell-to-cell process uniformity with objective and repeatable resistance measurement:

- Predict when plating fingers have to be serviced using measured mean resistances. Increase yield

across various plating cells in the tool by detecting the increase in contact resistance in real time.

- Quickly monitors and identifies resistance measurements with 50 separate measurement pads

around the perimeter, utilizing Kelvin Sensing (4-wire resistance) method for accurate

measurement of low value resistance

Shorten equipment maintenance cycles with wafer-like 4-wire resistance sensor:

- Collect and monitor real time measurement of contact resistance plating cells to detect residue

affecting plating pins. Thinner wafer-like form factor allows ARS to be handled like any other

wafer in the tool. Save time and costs associated with metrology wafer measurements.

Predict when a tool needs maintenance with quantitative analysis of measured mean resistance over time:

- Optimize preventative maintenance plans with accurate, repeatable data trends. Record data to

enable comparison between past and present, as well as one tool to another with new

CyberSpectrum™ software. Establish and save a baseline from a known clean and new contact

ring. Compare mean resistances to baseline values and receive early warnings for non-uniform

deposition associated with changes to plating pins:

Improve cell-to-cell process uniformity with objective and repeatable resistance measurement:

- Predict when plating fingers have to be serviced using measured mean resistances. Increase yield

across various plating cells in the tool by detecting the increase in contact resistance in real time.

Download data sheet