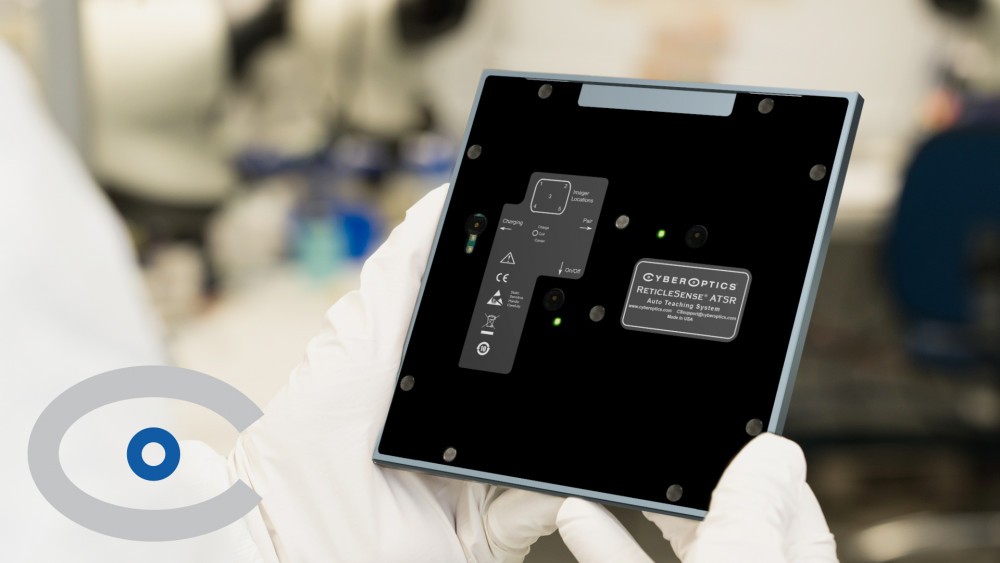

Nordson Test & Inspection - ReticleSense® Auto Teaching System™ (ATSR)

Improve equipment set-up and long term yields by wirelessly capturing three dimensional off-set data (x, y and z) in real-time to quickly teach reticle transfer positions for proper alignment and set-up of semiconductor tools.

Benefits:

- Improve yields and lower particulate contamination with accurate reticle handoff calibration.

- Capture offset data for accurate calibration of transfer positions as the reticle-like ATSR moves through your semiconductor equipment.

- Improve the yield of your manufacturing process with properly calibrated equipment.

- Achieve repeatable and reproducible semiconductor equipment setups.

- Eliminate technician-to-technician variation with the ATSR calibration that enables repeatable and reproducible setup and maintenance checks.

- Reduce equipment downtime from hours to minutes.

- Save time troubleshooting as the wireless and vacuum compatible ATSR allows equipment to remain sealed during inspection.

- Increase equipment availability while reducing manpower and consumable expense.

- Speed troubleshooting and lower consumable expense with visual inspection.

New :

CyberSpectrum™ software graphical user interface provides x, y and z offsets that eliminate guesswork. Search for lost wafers and pedestal debris without opening the tool.

Benefits:

- Improve yields and lower particulate contamination with accurate reticle handoff calibration.

- Capture offset data for accurate calibration of transfer positions as the reticle-like ATSR moves through your semiconductor equipment.

- Improve the yield of your manufacturing process with properly calibrated equipment.

- Achieve repeatable and reproducible semiconductor equipment setups.

- Eliminate technician-to-technician variation with the ATSR calibration that enables repeatable and reproducible setup and maintenance checks.

- Reduce equipment downtime from hours to minutes.

- Save time troubleshooting as the wireless and vacuum compatible ATSR allows equipment to remain sealed during inspection.

- Increase equipment availability while reducing manpower and consumable expense.

- Speed troubleshooting and lower consumable expense with visual inspection.

New :

CyberSpectrum™ software graphical user interface provides x, y and z offsets that eliminate guesswork. Search for lost wafers and pedestal debris without opening the tool.