News

AFORE will present its BRAND NEW 'METIS' System @Sensor+Test, 30.5. - 1.6. 17

The BRAND NEW METIS is a motion simulator for sensor and end product testing which will officially be launched at this year's Sensor+Test Show in Nuremberg from 30th of May until 1st of June, 2017 on Afore's booth # 5-422.

Click here for more Information about the METIS System.

IS-Test Workshop will take place next week, May 15th and 16th

ITWS is a regular event for the semiconductor industry in Europe.

This year it's already the 9th anniversary of the Workshop and it focuses on the topic 'To test or not to test? A closer look on wafer testing strategies.

AFORE OY @Sensor + Test Show in Nuremberg from May 30th to June 1st

Afore Oy will exhibit its latest development for MEMS device testing under stimulus at the Sensor + Test 2017 show taking place in Nuremberg, Germany from May 30th to June 1st, 2017.

We invite our customers to visit their booth #422 in hall 5.

htt Group is the new Sales Rep of MPI's Advanced Probecards

From June 1st, 2017 htt Group will be the new official Sales Distributor of MPI's Advanced probe Cards.

MPI’s probe card technologies have the world’s lowest overall cost-of-ownership for the vast majority of semiconductor testing:

- Cantilever

- Vertical

- MEMs

See Japan Unix' innovative Robot Technology in Selective Soldering

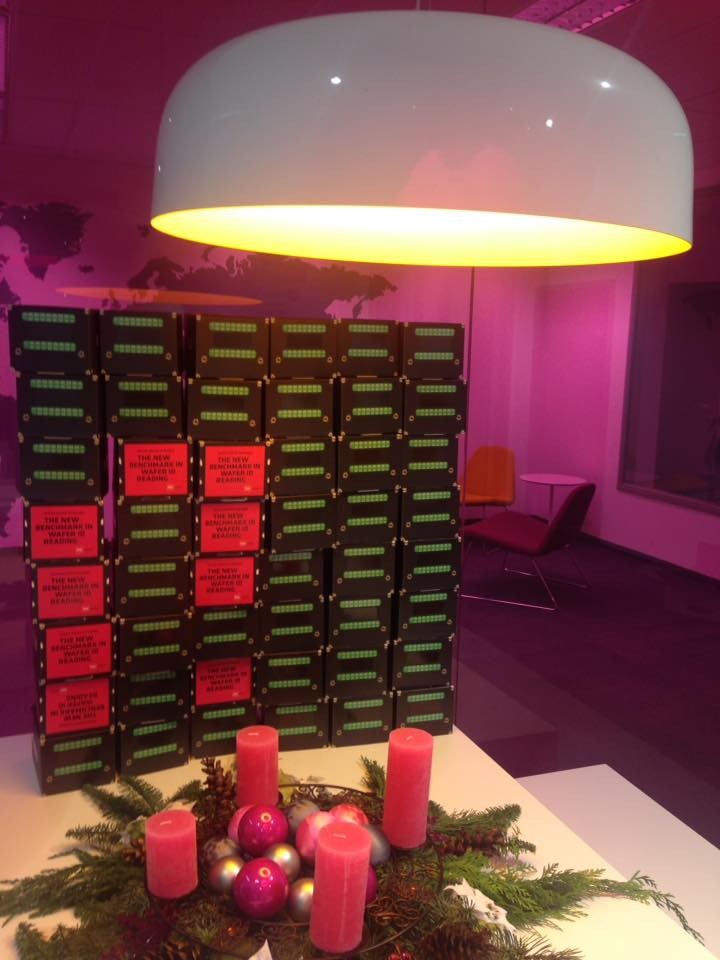

htt Group's Wafer Reader Division @Semicon SEA

htt Group's product Manager for IOSS Wafer ID Reader will be on site at Semicon SEA, booth # 113 to give Live Demos of the brandnew IOSS WID120 Wafer ID Reader.

HTT Probecard Division turns 25! Let's celebrate!

„25 Jahre HTT Prüf Karten aus Fertigung Dresden“

Am 16.März 2017 war der Start der HTT Dresden. Begonnen wurde mit der Fertigung von Blade Type und Epoxy Type Probe Karten in den Fertigungsräumen, Dresden , Grenzstrasse Erste Mitarbeiter waren unser Prüfkartenbauer Dietmar Reichelt und Axel Thierschmann und unser Fertigungsleiter Falk Schöne, seine hohen Prüfkartenkenntnisse haben die Prüfkarten-Branche in den 25 Jahren sehr erfolgreich geprägt, die Industrie kennt unseren Falk, fragt nach seinem Rat und spricht von ihm nur in den höchsten Tönen, für sein Prüfkartenteam ist er Vorbild und ein immer gerechter Chef.

Durch das starke Wachstum der HTT Dresden Prüfkartenfertigung und der damit verbundenen Bereitstellung von modernen und neuen Fertigungsgeräten für die heute 15 Mitarbeiterinnen und Mitarbeiter war der Umzug 2002 in größere und moderne Fertigungsräume zur Wetterwarte, nahe dem internationalen Flughafen Dresden unausweichlich. Heute arbeiten unsere Dresdner Kolleginnen/Kollegen unter Reinraumbedingungen und unterstützt von modernsten Materialbearbeitungsmaschinen, Probekartentestern, vielen eigenentwickelten Geräten, sowie Hilfsmitteln wie CAD und modernen CRM- und Computersystemen hoch motiviert und sehr erfolgreich und mit höchster Qualität von der Wetterwarte aus.

Die HTT Dresden ist seit 2011 nach ISO 9001:2008 zertifiziert und entwickelt und fertigt heute Prüfkarten, Mini Prober und Specials und betreut und beliefert mehr als 200 Kunden . In den sehr erfolgreichen 25 Jahren haben unsere Prüfkarten Spezialisten mehr als 3.000 Layouts und Designs neu erstellt, über 60.000 Prüfkarten neu gebaut, 5.500 Prüfkarten repariert und mehr als 40 Mini-Prober (der kleinste Prober der Welt) im Kundenauftrag entwickelt und gebaut.

Herzlichen Glückwunsch unserem Leiter der Prüfkarten Dresden Fertigung, Herrn Falk Schöne und seinen 6 Kolleginnen und 8 Kollegen. Wir feiern unser 25-jähriges Jubiläum am Freitag, 21. April 2017 von 13 Uhr bis 17 Uhr in Dresden, zur Wetterwarte 50, Haus 337 b. Wir freuen uns auf Ihr Kommen.“

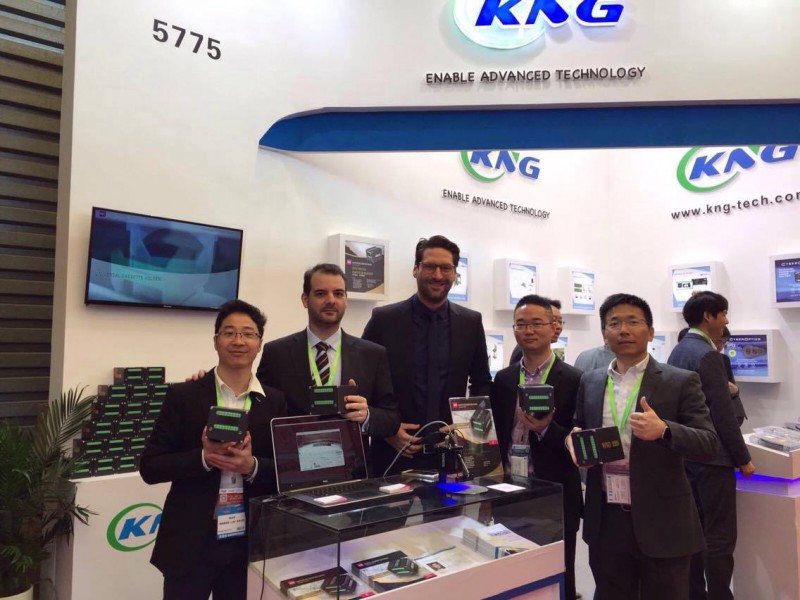

Thank you Semicon China 2017 for having us!!

We had a sucessful Semicon China Show in Shanghai with lots of live Demos of the brand new IOSS WID120 Wafer ID Reader.

For more Information about the WID120 please click here

htt Group Wafer Reader Division @SEMICON CHINA, next week!

htt Group will be @KNG's booth No. 5775 at Semicon China from 14th fo 16th of March, 2017.

For more Information about the Show please click here:

http://www.semiconchina.org/

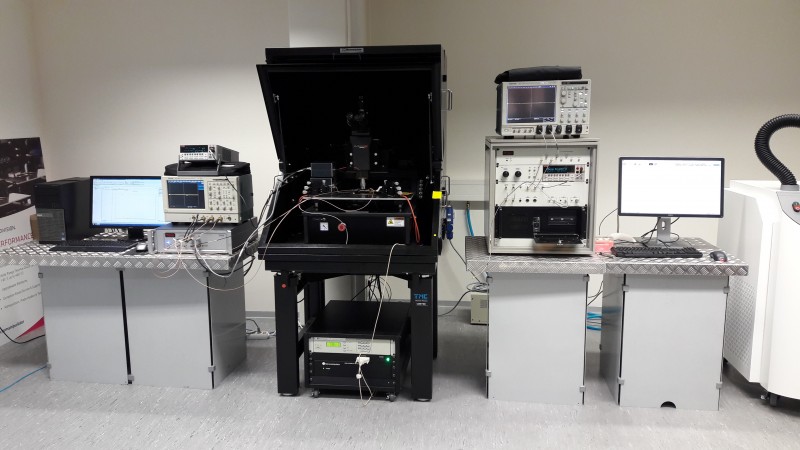

Thermo Fisher Sceintific 2-pin ESD Tester Seminar @htt.

htt recently hosted a Thermo Fisher Scientific 2-pin ESD tester seminar showing attendees how to bring ESD characterization of their devices to the next level.

The seminar included hands-on operation at both the TLP/VF-TLP tester Celestron as well as on the HMM / HBM / MM tester Pegasus.

Both systems were set up to test wafer level devices at a Micromanipulator probe station in our demo room.

Click here for more details on Thermo Fisher Scientifics ESD test solutions.

http://www.httgroup.eu/divisions/equipment/capital_equipment.php?label=35

Fully automatic 5-axle milling System installed @PC Production in Dresden

The Dresdener Probecard Production exdented its production process with a new modern 5-axle milling machine which enables to manufacture ceramics in a high-precision quality.

For more Information about our in Dresden manufactured Probe Cards please click here

htt Group wishes you all a Merry Christmas xxx

htt Group had a successful show @Semicon Japan

SEMICON EUROPE SHOW - 25th to 27th of October

new htt Dresden Image Movie - see it here

ANNOUNCEMENT - htt Group is the new sales Rep of MiS KOREA

MIS Auto Decaper is the world’s first automated robot system that safely and effectively removes the surface molding (EMC: Epoxy Molding Compounds) of packaged semiconductors and electronic parts.

It is the only machine that can substitute the existing decapsulation work that is mostly done by hands and several machines. In addition, MIS has released the world’s first etching machine, Deprocessor (Auto Wet Station) that can decap micromini semiconductors and can do the partial etching work for silicone chips and the delaminating work (which has the precision of micro meter) that selectively and safely delaminates the layer of the chip composed of several layers.

For this, in December 2005, MIS made a contract for joint technical execution with Korea Institute of Science and Technology, and worked on the research and development. The project was selected by Samsung Electronics as a strategic task and in February 2007, MIS Auto-Deprocessor (Auto Wet Station) was developed and supplied. And then, it was acknowledged by the Korea Development Bank in terms of its technology and business possibility so it successfully attracted some funds from it and since then, MIS has been doing its best.

The semiconductor etching work needed several machines and dangerous manual works, but now it can be done by 1 unit of MIS auto robot system. MIS has been putting its focus on the development of the equipment making prompt and precise work performance. As a result of the efforts, now MIS can guarantee safety in working for those who use equipment, and further, it can bring the improvement in working efficiency and the remarkable reduction of production costs to customers.

MIS will keep working on research and development, and will exert itself to develop new and innovative products with the best performance in the fields of nano processing systems and displays. MIS will do its best for customer satisfaction. Click here for more information about MIS Korea's products.

READY for THIN wafer application NOW - mBWR200 V4!

The mBWR200 is available for THIN wafer applications now.

With the new designed concept of the mBWR200 it is possible to handle wafer sizes from 250µm up to 1100µm. For more information please contact your HTT Wafer Reader Division.

For more product details about Mechatronic mBWR200 please have a look here.

ANNOUNCEMENT - htt Group is the new sales Rep of Japan Unix

The Japan Unix provides products for soldering automation, which features many ingenious offerings including inline soldering robot, desktop soldering robot and soldering modules.

Those were designed based on their unique soldering method and automation expertise. The lineup includes a wide array of models, options, and technical methods to allow customers to select the optimum configurations to meet their needs.

Japan Unix provides the best solution for customers facing such issues as lead-free, heat dissipating circuit boards, and high thermal capacity components.

For more information about Japan Unix and its product range click here

ANNOUNCEMENT - htt Group is the new sales Rep of TPS Thermal Product Solutions

Thermal Product Solutions (TPS) designs and manufactures industrial and laboratory ovens and furnaces, and environmental temperature cycling and stability test chambers. Product brands include Blue M, Gruenberg, Lindberg/MPH, Tenney, Wisconsin Oven, and Baker Furnace. TPS headquarters are located in New Columbia, Pennsylvania. Baker Furnace is located in Yorba Linda, California, Lindberg/MPH is located in Riverside, Michigan, and Wisconsin Oven is located in East Troy, Wisconsin.

For more product information and details click here