News

Wid120 Wafer ID Reader working on green and blue light for SiC wafers

Did you know that our WID120 can read nearly all different kinds of codes such as OCR, Barcode, DataMatrix and QR codes?

But, there's more, SiC, GaN & Si!

It is also the ultimative OCR Reader for high reflective materials, especially wafer - including SiC wafers. Contact our Reader Sales and Technical Team to receive full knowledge about the performance of our WID120.

Watch the below video to get a deeper understanding about our #wid120 #waferidreader working on green and blue light for SiC wafers.

What a great Semicon Europa 2023! Thank you!

Semicon Europa is around the corner - save your FREE TICKET FOR THE SHOW

Click here to receive your FREE TICKET for Semicon Europa

htt Group new Sales Partner of Reid Ashman

We are happy to announce that we are the new Sales Partner of Reid Ashman, known for inventing the testhead manipulator.

Reid-Ashman has achieved and maintained its position as the world’s leading supplier of mechanical solutions to the semiconductor test industry through hard work and providing total customer satisfaction.

htt Group @Semicon Taiwan!

Summer is not even over but trade fair season in the Semiconductor Industry will already start in 2 days!

We will join our friends of MPI Corporation at their booth at Semicon Taiwan to give LIVE DEMOS of our #wid120 #waferidreader - The new benchmark in wafer ID reading!

Our Senior Product Manager Sergio Marques will be on site and happy to see you there!

#semicontaiwan #semicontaiwan2023 #semicon #semiconductor #waferidreader #sic #gan #siliconcarbide #galliumnitride #hightechtrade #hightech #httgroup #httgrouparoundtheworld #httgroupintaiwan #halbleiter #readerdivision #allyoucanread #tomorrowstechnologytoday

FREE CYBEROPTICS WEBINAR: WaferSense® Auto Gapping System AGS

This time the WaferSense® Auto Gapping System AGS will be the main topic. The AGS improves uniformity and yield for accurate and repeatable setup.

Semiconductor fabs and OEMs worldwide value the accuracy, precision and versatility of the WaferSense AGS – The most efficient and effective wireless measurement device for chamber gapping.

Some of the main benefits of the AGS are as follows:

- Achieve the ideal set-up for your equipment by measuring gaps at three points.

- Improve tool-to-tool process uniformity with objective and repeatable gap adjustments.

- Reduce equipment calibration time through live feedback.

- Speed setups, maintenance and troubleshooting with automatic handling

35 YEARS HTT GROUP - a little recap ;-)

CELEBRATE GOOD TIMES ;-)

On July 1st, htt group officially turned 35 years and we collected some special memories of the past 35 years!

Enjoy watching our little movie and let's kick off the next 35 years!

SEMICON CHINA is finally back!

Visit us on site! We are happy to meet you in person for a chat!

We are also providing LIVE DEMOS of our WID120 Wafer ID Reader - the new benchmark in Wafer ID Reading!

htt Group at Silicon Saxony Day!

Come by and say Hi at our small booth during Silicon Saxony Day.

Our CEO of our probecard Division in Dresden will be on site to give you some insights about our made in Germany Probecards.

Our product range includes #Cantilever or #Blade Type #probecards, single and multiple test, for cold and hot test temperature, special probe cards and our #MiniProber which tests small pieces of a wafer. Additionally, in our European Probe Cards Repair – and Servicecenter in Dresden our team provides repairs of all kinds of standard and advanced Probe Cards as well as repairs of advanced Probecards from MPI Corporation!

See you in Dresden!

Visit us at EMLC Mask & Litography Conference in Dresden!

We will have a small team and a booth during #emlc mask and lithography conference starting today, 19th of June in Dresden, Hilton Hotel. Who else will be there and up for a chat?

Our Michael Schartner and our founder Eberhard Siml will be on site to give LIVE DEMOS of the #wid120 #waferidreader from IOSS GmbH.

Also, one of our friends from CyberOptics, Mr. Shawn Malek will be on site to give live demos of the ATSR and ATS2 WaferSense® Wireless Measurement Devices.

#emlc #emlc2023 #mask #lithography #cyberoptics #wafer #wafersense #httgroup #httgroupatemlc #dresden #waferreader #seeyouatemlc2023

SWTest in Carlsbad - we will be there!

SWTest Conference is the biggest and most known conference for Semiconductor Wafer Test in the industry, taking place this year from June 4th to 7th in Carlsbad near San Diego, California, USA.

MPI Corporation as a Platinum Sponsor of the event, together with HTT Group as the distributor and service partner for MPI Probecards & MPI Thermal Streamers in Europe, cordially invite you to our Hospitality Lounge & Party at the Workshop Resort Hotel!

Looking forward to meeting you on site!

HI FROM SEMICON SEA!

Come by and say Hi at ZMC's booth No. C316 at Semicon SouthEastAsia in Penang!

We will give LIVE Demos of the IOSS WID120 Wafer ID Reader which reads even damaged codes (high reading rates of OCR, Barcode, DataMatrix and QR codes).

Semicon South East Asia in Penang will start on 23rd of May, 2023!

Visit us at our partner ZMC's booth No. C316 for LIVE Demos of the WID120 Wafer ID Reader - the new benchmark in Wafer ID Reading due to its ability to also read damaged codes such as OCR, Barcode, DataMatrix and QR Codes!

Take your LFC knowledge to the next level

Learn about new high-speed LFC technology!

Liquid Flow Controllers are used to precisely control flow rates of liquid precursors for Chemical Vapor Deposition (CVD) or Atomic Layer Deposition (ALD).

Recently, technology advancement has led to LFCs with a 4x improvement in sensor speed, which leads to faster time to set-point and tighter flow control. In microelectronic applications this can result in significant gains in throughput and yield, while at the same time reducing liquid waste. MSP offers a broad portfolio of Vaporizers, Liquid Flow Controls and Filters for your CVD and ALD needs.

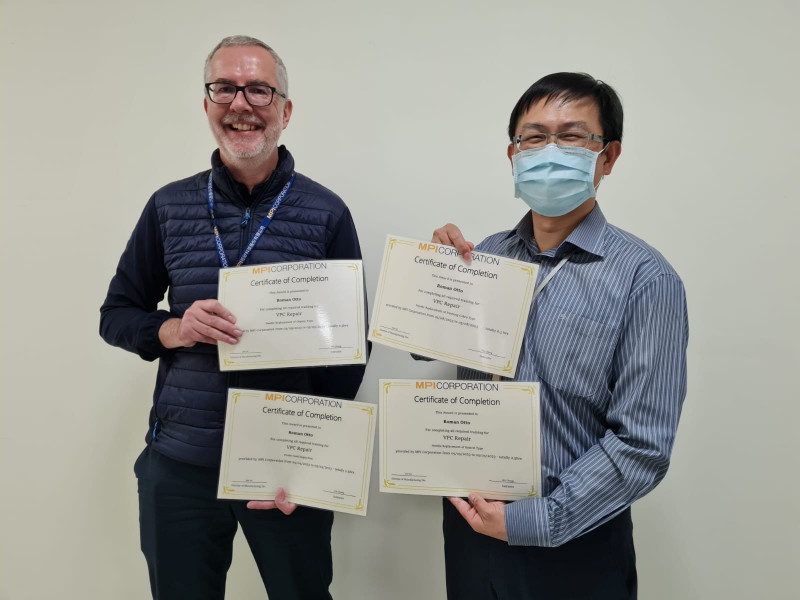

Training at MPI Taiwan!

Last week, 2 of our #probecardspecialists had the opportunity to stay in Taiwan at our friends from MPI Taiwan to do an onsite training on their products and repairs.

Roman and Mike had an incredibly great time at with all the great MPI guys in Taiwan.

Not only during the workshop times where they gained deeper knowledge about the MPI Probecards, but also at the weekend and late into the night they were able to experience the incredible warmth and hospitality of the Taiwanese.

A special thanks to Steven and the rest of the great MPI Team!

The HTT-MPI family has a relationship that is very rare to find.

THANK YOU MPI for your trust and continuous support!

Let's continue our good cooperation!

#mpitaiwan #thankyou #probecards #mpiprobecards #httgroup #httgroupprobecards #httgroupprobecarddivision #httgroupdresden #businessfriends

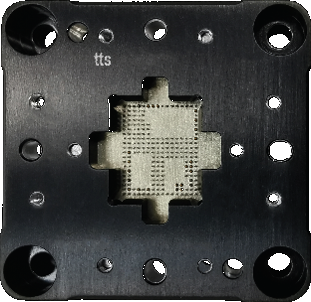

TTS Test Tooling Solutions - High Pin Count, High Speed, High Frequency Test Sockets

Test sockets by TTS:

Coaxial Socket:

Coming out with the high speed test generation, TTS provide a reliable solution based on accurate simulation, considerate design and precise machining. Focus on customer experience, TTS provides the most suitable solution which with customized socket to fulfil the testing condition, environment and so on. With high insistence on quality, coaxial socket can achieve high reliability and longer life.

High Frequency & mmWAVE:

Conventional RF socket design which doesn't require shielding technique. Easy socket and pin maintenance. Provide longer lifespan compare to elastomer contact.

10,000 High Pin Socket:

The major challenge of big package with high pin counts is warpage issue. TTS able to custom made Pin & Socket by simulation for optimum design solution to overcome co-planarity variation for stable contact to prevent intermittent contact failure.

Air & liquid cooling solution are available for high power heat dissipation on high pin count requirement.

TTS’s Test Sockets bring perfect testing solutions to any kind of package.

With supported pin counts up to 10k, pitches down to 0.30mm, temperatures between -40 and +150°C, High Frequency above 110GHz and High Speed topping 200Gbps, TTS technology showcases decades of experience, know-how, and research.

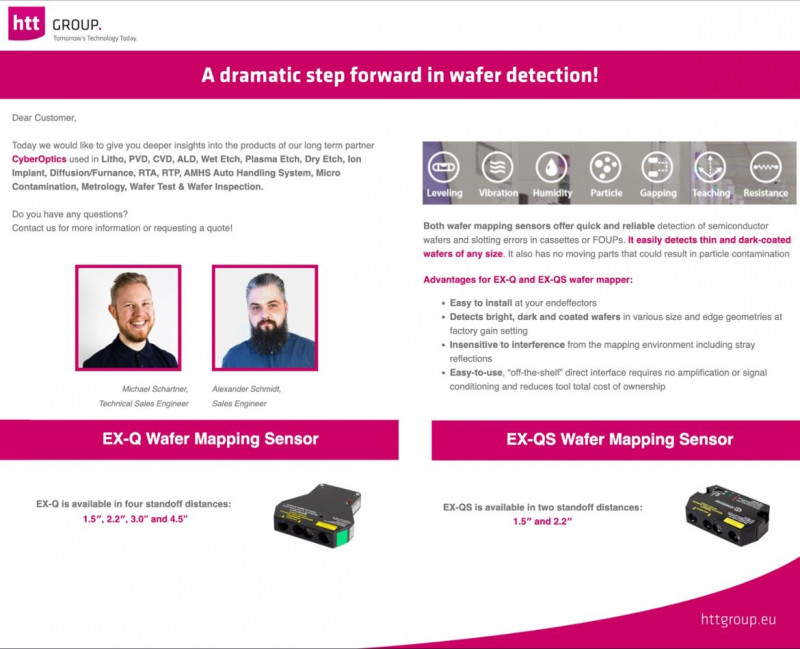

Cyberoptics Wafer Detection

A dramatic step forward in #waferdetection!

The #wafermappingsensors of CyberOptics

Read more below or contact our Sales Engineers for #cyberoptics Michael Schartner and Alexander Schmidt !

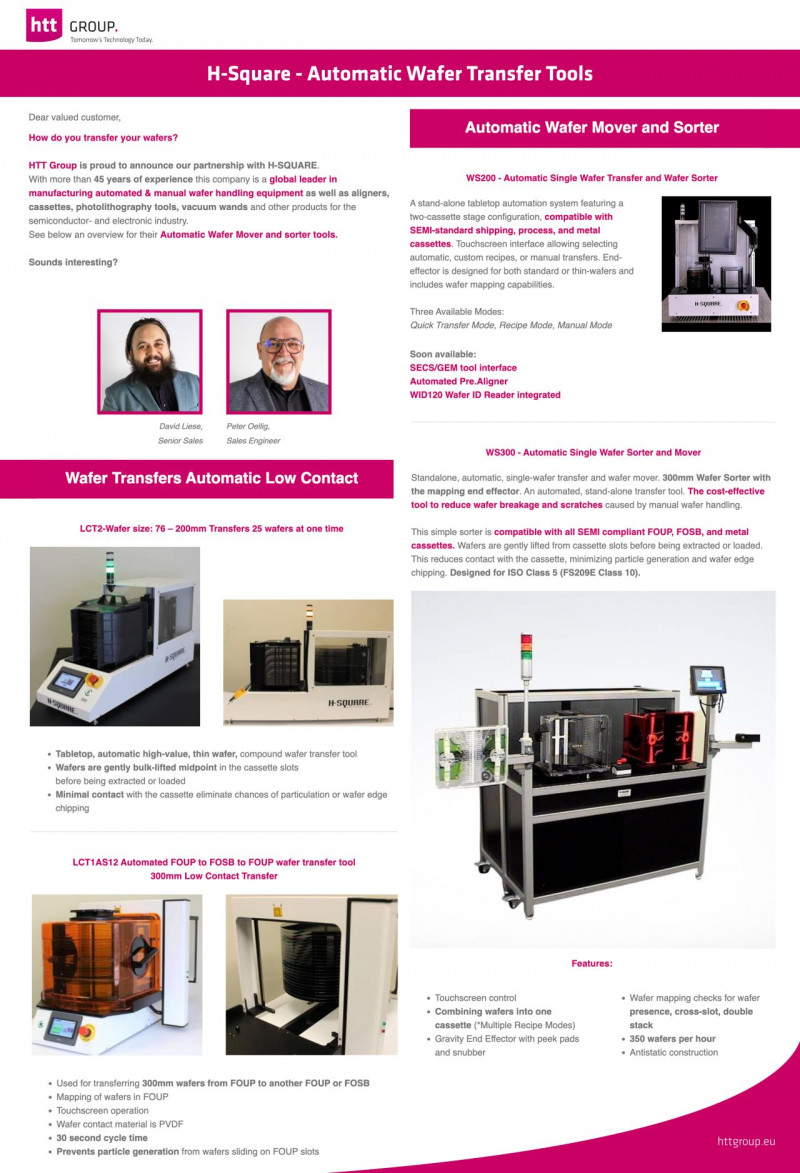

H-Square Wafer Transfer Tools

Learn more about H-Square's Automatic Wafer Transfer Tools and do not hesitate to contact us for deeper information and details about their products!

More Infos on H-Square products here

H-Square & htt Group

We are proud to be one of the 3 Sales Partners in Europe!

We proudly present our new product line TTS Group!

htt Group is the new Sales representative of TTS Group for Europe! We are looking forward to working together with this great company.

Since 1979, TTS Group has dedicated itself to providing the best possible solutions for solving the most challenging issues in the semiconductor test industry. With complete integration of our R&D, design, simulation, validation, and manufacturing, we focus our efforts on lowering the total cost of test with a relentless pursuit of innovation in yield improvement, quality, and product reliability. TTS Group understands our customer requirements and can provide a one stop solution for all their testing needs and concerns.